24hr Media for Dummies

24hr Media for Dummies

Blog Article

The Facts About 24hr Media Uncovered

Table of ContentsUnknown Facts About 24hr MediaRumored Buzz on 24hr MediaIndicators on 24hr Media You Should Know24hr Media Fundamentals ExplainedUnknown Facts About 24hr Media

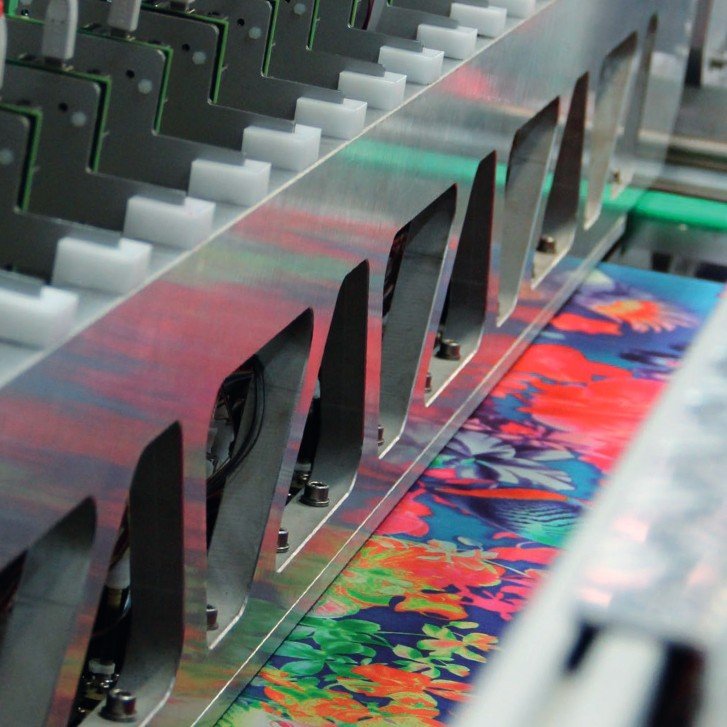

Innovations in print modern technology are changing the interactions playing field when it concerns quality, affordability and sophisticated capacities. Countered printing and electronic printing are the significant processes by which print work are embarked on both using four-color printing methods. Each option has its advantages, providing different strategies to fulfill the demands of varied production tasks.

Usually, this has actually been one of the most regular strategy for precisely maintaining shade matches, making it perfect for print runs that just call for fixed printing such as pre-printed forms, brochures, leaflets, service cards, and bulk postcard mailings. Due to the fixed nature of litho printing, it is not excellent for variable print items that will be sent by mail to individual receivers such as declarations, letters, and customized postcards.

More About 24hr Media

The most current innovations in print innovation are helping to bring many of countered's advantages right into the electronic printing world really transforming the face of contemporary printing! There are some key differences in between Offset Printing and Digital Printing.

Today's digital print equipment is among the most sophisticated on the marketplace. Below are some of the most significant benefits of using electronic printing: control the electronic print area, with full-color printing finished in one procedure and flawlessly printed straight from a print data. Without a lengthy set-up process, the calibration time of a particular job is reduced, contributing to quicker print time and general delivery.

The inkjet printing process has helped to change the sector in addition to the quality and rate of the output. The most current inkjet modern technology can print on typical offset stocks with dull, silk, and shiny coatings. High-quality digital print paired with software-managed shade monitoring methods adds optimum value to print pieces and makes production procedures a lot more reliable than offset.

How 24hr Media can Save You Time, Stress, and Money.

(https://www.reddit.com/user/za24media/?rdt=45067)

Eco-friendly and biodegradable inks and toners are additionally available for even more lasting printing. Digital print likewise removes the need to wash plates or blankets with dangerous chemicals at the end of the printing process.

Variable information helps businesses reach their specific customers and target market with uniquely-created and personalized content. As technology boosts, the high quality of digital printing has become second-to-none, with better detail, shade suit capabilities and overall precision. Without the need to clean plates or utilize excess ink, electronic printing is likewise much less wasteful and normally a lot more ecologically friendly.

Conventional printing techniques, such as offset lithography ("countered") and flexography ("flexo"), include multiple make-ready actions to transfer an initial image to a substrate. These methods need the manufacturing of a series of plates installed on a cyndrical tube to transfer ink that creates the preferred image when incorporated on paperboard and other packaging products. Window Vinyl.

The Basic Principles Of 24hr Media

Digital printing, with fewer moving pieces, is more agile than offset in this regard.

Reduced set-up time conserves money on the front end. And since these are not massive mass orders, smaller companies can afford to publish without having to fulfill the greater and much more pricey print limits of conventional printing.

Make sure you team up with a printing and product packaging partner that has the appropriate accreditations. While eleventh-hour printing and customization are a huge benefit, electronic may not constantly be the very best approach for you. For instance, balance out printing has the advantage of cost-effectiveness go to this site with big print runs, particularly those with sophisticated attractive results and specialty layers.

Little Known Questions About 24hr Media.

The favorable plate, with its smooth surface, draws in oil-based inks and fends off water. In contrast, the unfavorable plate, with its harsh structure, takes in water and fends off oil. Rubber rollers are then utilized to move the image from the plate to the corrugated surface area.

Corrugated paper can in some cases prove to be a difficult surface area to print on, however Litho prints to a separate surface and is after that laminated to it, making it very easy to publish top quality photos. It can be exceptionally consistent, also for futures. In reality, the much more you publish, the less costly the costs end up being for Litho.

What Litho doesn't provide you is precisely what Digital does, personalization. Costly set up Longer turnaround No Variable Data Printing Smaller sized shade range, shades can be much less bright Digital printing is the process of printing digital images directly onto the corrugated substrate making use of a single-pass, direct-to-corrugate strategy.

Report this page